-

Telephone

OUR SECTORS WE SERVE

We cast products with weights ranging from 1gr* to 50kg and dimensions ranging from 1mm to 500mm.

Why Orta Anadolu

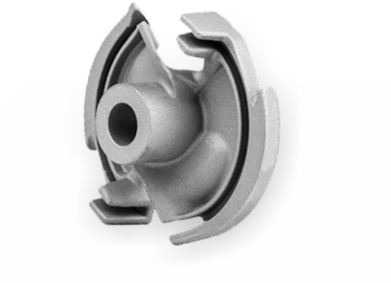

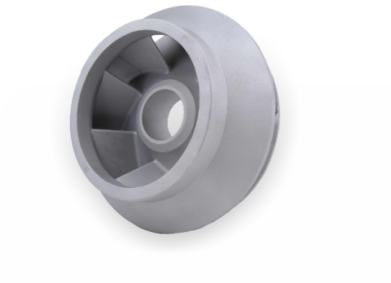

Every Detail Matters: Precision Casting Subtleties

- Fine Details and Complex Geometries

• Ability to successfully realize complex and finely detailed designs with machining capabilities.

- High Quality and Tolerances

• Ability to successfully realize complex and finely detailed designs with machining capabilities.

- Good Surface Quality

• Ability to ensure high surface quality in processed products and achieve aesthetic value that will meet customer expectations.

- Reduced Material Waste

• Minimizing waste and a sustainable production approach by optimizing the use of materials in manufacturing processes.

- Applicability in Various Materials

• Ability to address a wide range of materials with production and processing capabilities in different materials, such as metals, ceramics or polymers.

Technology

The Fineness of Technology Finds Its Shape with Precision Casting

OUR WORKING PRINCIPLE

Creativity of Fine Craftsmanship: The Power of Precision Casting

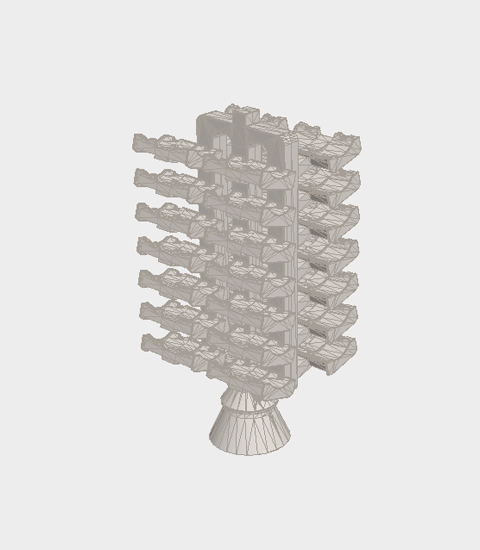

Design and Mold Preparation

The first step is to design the part to be produced. Detailed and complex geometries are taken into account at this stage.

Material Selection and Preparation

The material to be used in investment casting is selected in accordance with the characteristics of the part and its intended use.

Casting Process

After casting, the material is waited to cool. This process ensures that the part acquires the desired properties.

Part Processing and Quality Control

The cooled part is removed from the mold and processed. It is done to improve the surface quality or prepare it for assembly.

News